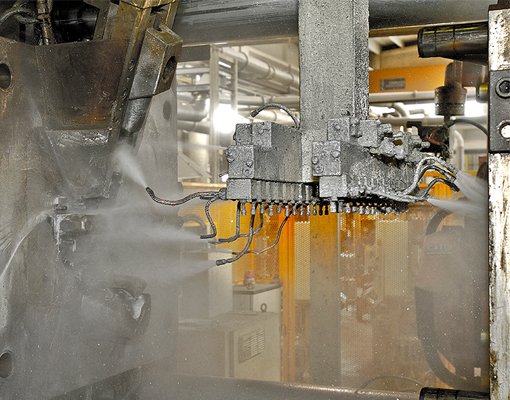

Pressure die casting is a quick, reliable and cost-effective manufacturing process for production of high volume, metal components that are net-shaped have tight tolerances. Basically, the pressure die casting process consists of injecting under high pressure a molten metal alloy into a steel mold

Unicote FI Series die casting release agent is water base lubricants developed for aluminum zinc and magnesium die casting application.

Types of Die Lube

1)Regular Grade

2)Customize Grade

Water base dycote- Unicote water base dycote is based on micro emulsion technology added with special additives in order to get good releasing & shining over the component and which can be easily diluted with water in order to get a high dilution rate. Some of the polymers required for water base are being selected from reputed source and its blending is done in india due to which we can provide cost effective quality product supplying to almost every sector in die casters such as

Led ,Automobile, machinery etc

Plunger Lubricant is designed to specifically reduce friction and to extend plunger tip and sleeve life. This results in excellent efficiency and has the most desirable chemical and physical qualities to function in the Unique Fluxes And Lubricants. Unicote plunger lube oil base lunger lubricants use for smooth running of piston.

Unicote Lube- Unicote Lube is based on mineral oil added with polymers so that it can be applied on dyes for easy releasing of critical component without any casting mark and the same lube can be applied on plunger tips for smooth running of plunger

Types of plunger lube

1)V-Series

2)M-Series

Unicote Lube

Type of Coatings-

1)Antisolder Paste

2)Ladle Coating

Anti solder paste- Anti solder paste is used to remove the catching of aluminium from die surface where it is hard to provide the cooling line inside the dye.

Its comes in 1 kg pack so you can use according to your requirement while other pack remains as it.

Ladle Coating- It provide barrier between spoon and molten aluminium and hence increase the life of spoon.

Type of Fluxes-

1)Drossing

2)Covering

3)Furnace Cleaning

Coverflux-11 “SS” grade- our coverflux is especially formulated with exothermic additives in order to have a maximum recovery of aluminium from the dross.

Unicote Degasser an environmental friendly range of chemical degassing tablets for aluminum alloys.

There are type of Degasser-

1)Degasser 190

2)Non-smoke

Degasser - our degasser perform both the action of degassing hydrogen gas from the melt and at same time refine the grain of aluminium to minimise the porosity .our tablet is available in 50 gms and for 300 kg of melt 150 gm of degasser is sufficient to remove all the hy

drogen gas from the melt.

Non-smoke

We have spray gun along with their spares so if there will be any minor fault within the spray gun it can be replaced by thier spares and can be used again instead of replacing by whole new spray gun as in case of china make spray gun.

Unicote Paste- We can also provide the UNICOTE LUBE in the jell form by retaining all of its important properties.

Copyright ©2021 Unique Fluxes And Lubricants. Designed By Brand Bucket Softtech